---

Key Customization Methods:

Dongguan Fitwell Headwear & Bag Co., Ltd. specializes in premium hat customization through advanced techniques like embroidery, sublimation printing, screen printing, and 3D embellishments. Our services emphasize durability, precision, and creativity, catering to fashion, sports, corporate branding, and outdoor markets. Combining cutting-edge technology with skilled craftsmanship, we deliver tailored solutions—from bold logos to subtle textures—ensuring high-quality finishes for bulk or small-batch orders. Partner with Fitwell to elevate your brand with innovative, functional designs that stand out globally.

---

Key Customization Methods:

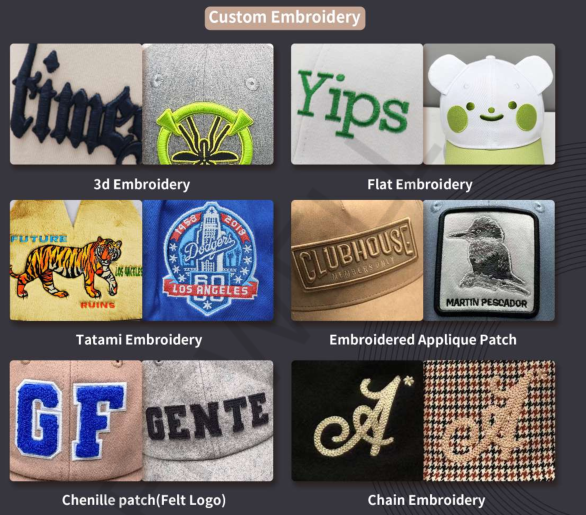

1. Custom Embroidery

Custom Embroidery involves stitching intricate designs onto hats using specialized machines and threads. Techniques include flat embroidery for simple logos, 3D embroidery for raised textures, and chain stitching for a retro aesthetic. Tatami embroidery uses dense, parallel stitches to cover large areas, while embroidered applique patches allow pre-made designs to be sewn o

nto the fabric. This method ensures durability and a premium finish, ideal for brand logos or detailed artwork. Fitwell offers color-matching and multi-angle adjustments to ensure precision and consistency across batches.

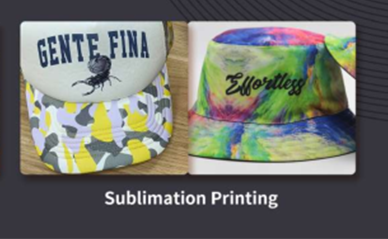

2. Sublimation Printing

Sublimation Printing uses transfer dye onto polyester-based fabrics, creating vibrant, fade-resistant designs. The process turns solid dye into gas, bonding with the fabric fibers for a smooth, crack-proof finish. It’s perfect for full-color gradients, or all-over patterns. Fitwell employs this technique for hats requiring complex graphics, such as sports team logos or fashion-forward designs. The result is lightweight, breathable, and long-lasting, with no texture alteration to the material.

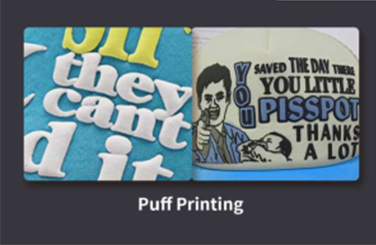

3. Puff Printing**

Puff Printing involves adding a foaming agent to ink, which expands when heated, creating a raised, textured effect. This technique adds depth and tactile interest to logos or decorative elements. Fitwell uses it for eye-catching designs on casual or streetwear-style hats.

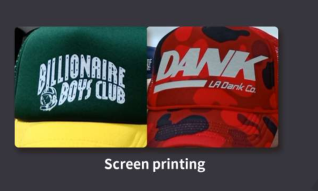

4. Screen Printing**

Screen Printing applies ink through a mesh stencil to create bold, opaque designs on fabrics. It’s ideal for simple logos, text, or block-color graphics. Fitwell uses high-quality plastisol or water-based inks for flexibility and durability. This method suits cotton, canvas, or blended materials, offering cost-effectiveness for bulk orders. Multiple layers can be added for multicolor designs, with precise registration ensuring sharp edges.

5. Debossed Logo**

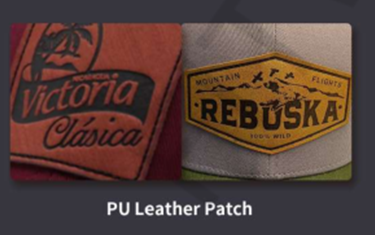

Debossing presses a design into the fabric or leather, creating an indented, subtle effect. It’s commonly used on PU leather patches or structured caps for a sophisticated, understated look. The process ensures long-lasting impressions without compromising material integrity.

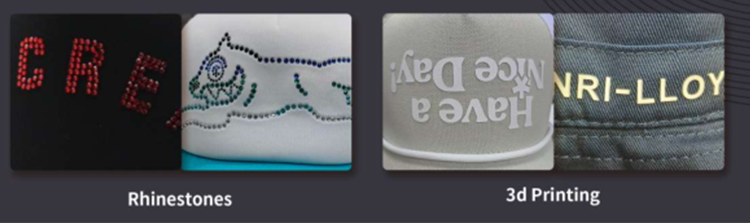

6. Rhinestones & 3D Printing**

Rhinestones are hand-applied or heat-pressed crystals for glamorous, reflective details. 3D Printing uses polymer materials to build textured, dimensional designs layer by layer. Fitwell combines these techniques for avant-garde or luxury hats, offering unique tactile and visual appeal. Both methods allow intricate customization, from geometric patterns to brand-specific motifs.

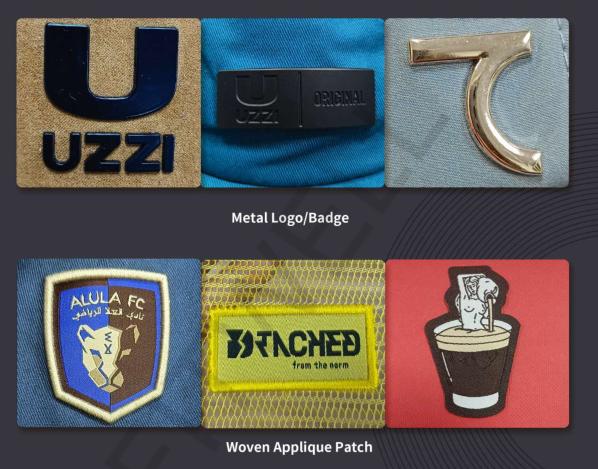

7. Metal Logo/Badge**

Metal logos or badges are crafted from stainless steel, brass, or zinc alloy, then attached via rivets or stitching. These durable emblems suit outdoor, military, or high-fashion caps, enhancing brand identity with a rugged or elegant aesthetic.

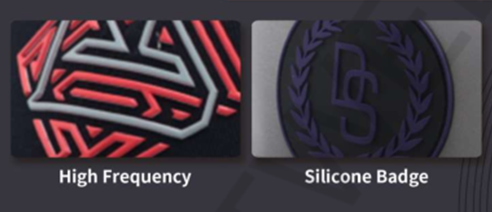

8. Silicone Badge & High-Frequency Embossing**

Silicone badges are molded into flexible, rubber-like logos, resistant to weathering and wear. High-Frequency (HF) embossing uses heat and pressure to fuse PVC or PU layers, creating seamless, waterproof designs. Fitwell utilizes these for sportswear or outdoor hats, ensuring logos remain intact in harsh conditions.